Vortex Freeze-Dried Technology (VFD)

The enzymes and microbes that naturally degrade these herbs require water to function. VFD dries our herbs with no exposure to heat at any time during the processing. The result is a stronger herbal powder (more highly bioactive) that is more easily absorbed and used by your body (more bioavailable). VFD takes freeze-drying to a new level.

In our process, the product is not sitting motionless on trays but is flying around inside the product chamber in a vortex. This dramatically increases the exposed surface area which, in turn, increases the rate of heat exchange allowing larger quantities to be dried faster and more thoroughly. Farm and Forest Fresh herbs as well as strict raw material specifications set the scene for a more effective and experiential herb, but truly, it is VFD that distinguishes THAI HEN-GO herbs from all others on the market.

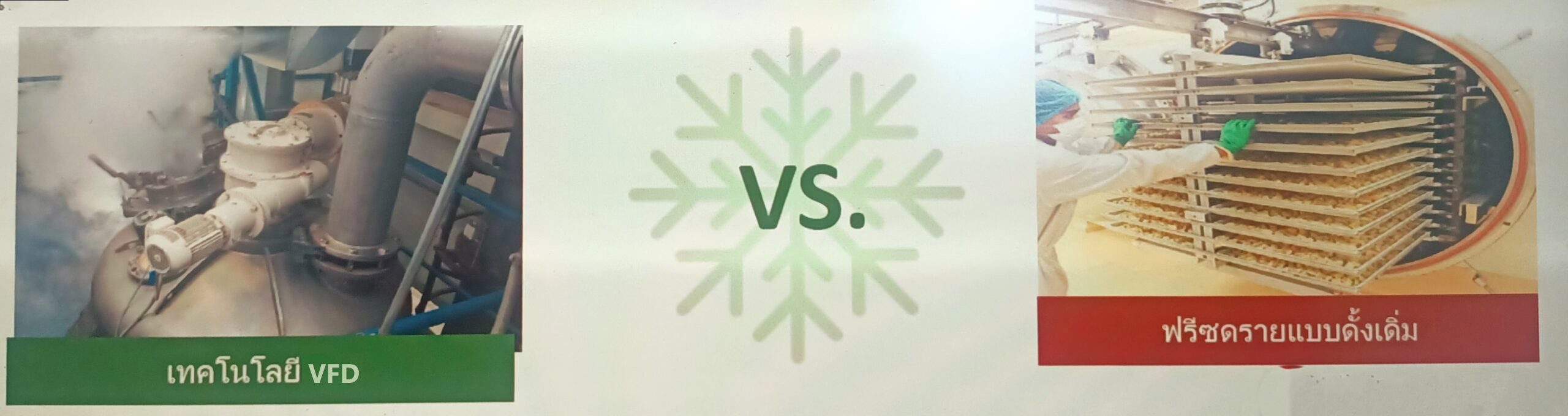

Differences in production process between VFD process and traditional freeze-dry process

VFD process

The herbs are frozen at temperatures of -40 to -50 degrees Fahrenheit. Once frozen, the freeze dryer begins to draw air out of the machine to create a vacuum and lower the pressure below atmospheric pressure, keeping the boiling point of water low. The temperature of the herbs gradually rises to just above 0 degrees Fahrenheit. The ice crystals in the herbs “sublimate” into water vapor without being converted to liquid, allowing the moisture to be removed from the herbs without the need to be “heated” at high temperatures.

Traditional freeze-dried

Dehydration by drying in a hot air oven or drying in the sun is a traditional method of reducing the moisture content of food by heating it for a period of 5 hours to 2 days to extend the shelf life of herbs.

High Pressure Steam Spraying(Retort) is the injection of high temperature steam at 121•c to sterilize the food, allowing it to be stored at room temperature for 1-3 years, but losing 50-60% of its nutritional value and changing its color, smell and taste.

Advantages of Vortex Freeze-Dried Technology (VFD)

- While these same herbs can be found growing elsewhere, our unique processing (VFD) is where the magic is made. VFD provides you with both unique selling points as well as barriers to competition.

- The biggest challenge of conventional freeze-drying functional superfoods and nutraceuticals is the high cost of machinery, operational costs, huge energy usage and small quantities produced. These factors combine to make conventional freeze-drying slow and expensive.

- In conventional freeze-drying the product is laid out on trays and the trays are placed on racks inside the product chamber. The exposed surface area (the drying surface) is limited, and only a small quantity of raw material can be processed.

VFD provides superior advantages, creating valuable market differentiation.

- In our VFD process, the product is not sitting motionless on trays but is flying around inside the product chamber in a vortex. This dramatically increases the exposed surface area which, in turn, increases the rate of heat exchange allowing very much larger quantities to be dried faster.

- While our process increases quantity and efficiency (expressed in lower costs) we also increase the quality. In the case of conventional freeze-drying the dried product must be mechanically ground into a fine powder. This intense grinding process can develop heat (due to friction) and hemorrhages the cells. With VFD Technology, the motion of the deeply frozen particles along with the sublimation of the ice structure that holds the particles together results in a fine powder that requires minimal or no grinding. The resulting porous particle structure is more bio-active (better preserved natural ingredients) and more bioavailable (more easily absorbed and metabolized).

Aqueous Ozone

With no heat and no chemicals or gamma radiation used in products, we need to handle the microbial plate count. This is accomplished by imitating nature which uses ozone to clean our water and air. This USDA and US FDA antimicrobial process eliminates the harmful microbes but does not harm the neutral and healthy microbes.